Wgs-l030 Laser Velocimetry and Length Measuring Instrument

60 000$

Negotiable

Condition:

New

Overview:

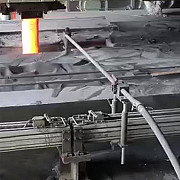

The WGS-L030 Laser Doppler Velocimetry developed by Wuhan CenterRise M&C Engineering Co., Ltd. is a measuring instrument for measuring the speed and length of the online, high temperature, and high-speed moving objects by using a high-precision laser Doppler velocity sensor. It is used to measure the speed and length of hot-rolled strips in rolling mills.

The WGS-L030 Laser Doppler Velocimetry mainly consists of two parts: hardware system and software system. The hardware system includes a set of laser Doppler speed sensors to measure the relative running speed of hot-rolled strips and sensors. The sensor arithmetic unit calculates the length of the steel plate passing through the sensor according to the measurement data of the laser Doppler speed sensors, and transmits it to the host system. The software in the host system calculates the speed and length of the hot-rolled strip according to the data of the arithmetic unit, and displays the relevant data and change curves. Alarm will occur according to the deviation threshold set by software system or manually, the hardware equipment is installed on the loop frame or L-shaped frame above the on-site measurement strip. The software system is mainly used to analyze and process the strip measurement data collected by the hardware system, and displays the speed and length data of the hot-rolled strip analyzed by the software in the display panel, and sends control and alarm instructions to the hardware system.

Measuring principle of the system:

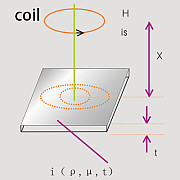

The working principle of the laser Doppler Velocimetry is shown in the figure below. The speed sensor is an instrument that uses the laser Doppler effect to measure the speed of fluid or solid motion. Usually it consists of five parts: laser, incident optical unit, receiving optical unit, Doppler signal and data processor. The main advantages of laser Doppler speed sensor measurement are non-contact measurement, linear characteristics, and high spatial resolution and fast dynamic response. The laser Doppler speed sensor adopts the LDV system of modern opto-electronics and microprocessor technology, which can more easily realize the measurement of the fluid or solid in 2D and 3D. The tracer particle of the laser probe uses the Doppler frequency shift of light scattered by moving particles to obtain velocity information. Since it is the laser measurement, the Doppler frequency has a linear relationship with the velocity and has nothing to do with the temperature and pressure. It is the instrument with the highest measurement accuracy of the speed in the world.

The composition plan of the system:

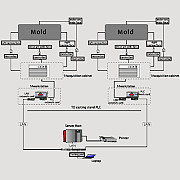

The fixed-length cutting scheme of the laser velocimetry and length measuring instrument adopts the system structure shown in the figure to realize a set of laser Doppler velocimetry and length measuring system. The sensors of the hardware system adopt a group of laser Doppler speed sensors erected on one side or above the measured slab to be inspected for vertical diffuse reflection installation. The hardware system transmits the collected data to the host system remotely. The measured speed data is integrated with the measured time to calculate the length of the measured slab and calibrate the shear. This method can get the high-precision and stable measurement data.

Parameters:

Slab width: ≥100mm

Slab length: >2000mm

Slab thickness: 1~300mm

Slab speed:

The WGS-L030 Laser Doppler Velocimetry developed by Wuhan CenterRise M&C Engineering Co., Ltd. is a measuring instrument for measuring the speed and length of the online, high temperature, and high-speed moving objects by using a high-precision laser Doppler velocity sensor. It is used to measure the speed and length of hot-rolled strips in rolling mills.

The WGS-L030 Laser Doppler Velocimetry mainly consists of two parts: hardware system and software system. The hardware system includes a set of laser Doppler speed sensors to measure the relative running speed of hot-rolled strips and sensors. The sensor arithmetic unit calculates the length of the steel plate passing through the sensor according to the measurement data of the laser Doppler speed sensors, and transmits it to the host system. The software in the host system calculates the speed and length of the hot-rolled strip according to the data of the arithmetic unit, and displays the relevant data and change curves. Alarm will occur according to the deviation threshold set by software system or manually, the hardware equipment is installed on the loop frame or L-shaped frame above the on-site measurement strip. The software system is mainly used to analyze and process the strip measurement data collected by the hardware system, and displays the speed and length data of the hot-rolled strip analyzed by the software in the display panel, and sends control and alarm instructions to the hardware system.

Measuring principle of the system:

The working principle of the laser Doppler Velocimetry is shown in the figure below. The speed sensor is an instrument that uses the laser Doppler effect to measure the speed of fluid or solid motion. Usually it consists of five parts: laser, incident optical unit, receiving optical unit, Doppler signal and data processor. The main advantages of laser Doppler speed sensor measurement are non-contact measurement, linear characteristics, and high spatial resolution and fast dynamic response. The laser Doppler speed sensor adopts the LDV system of modern opto-electronics and microprocessor technology, which can more easily realize the measurement of the fluid or solid in 2D and 3D. The tracer particle of the laser probe uses the Doppler frequency shift of light scattered by moving particles to obtain velocity information. Since it is the laser measurement, the Doppler frequency has a linear relationship with the velocity and has nothing to do with the temperature and pressure. It is the instrument with the highest measurement accuracy of the speed in the world.

The composition plan of the system:

The fixed-length cutting scheme of the laser velocimetry and length measuring instrument adopts the system structure shown in the figure to realize a set of laser Doppler velocimetry and length measuring system. The sensors of the hardware system adopt a group of laser Doppler speed sensors erected on one side or above the measured slab to be inspected for vertical diffuse reflection installation. The hardware system transmits the collected data to the host system remotely. The measured speed data is integrated with the measured time to calculate the length of the measured slab and calibrate the shear. This method can get the high-precision and stable measurement data.

Parameters:

Slab width: ≥100mm

Slab length: >2000mm

Slab thickness: 1~300mm

Slab speed:

Comments

0

You must Sign Up or Sign In to post your comment

Other similar ads

Metallurgical equipment

110 000$

Negotiable

Foreign city

9 February

Metallurgical equipment

100 000$

Negotiable

Foreign city

9 February

Metallurgical equipment

9 000₮

Negotiable

Foreign city

9 February

Metallurgical equipment

9 000₮

Negotiable

Foreign city

9 February